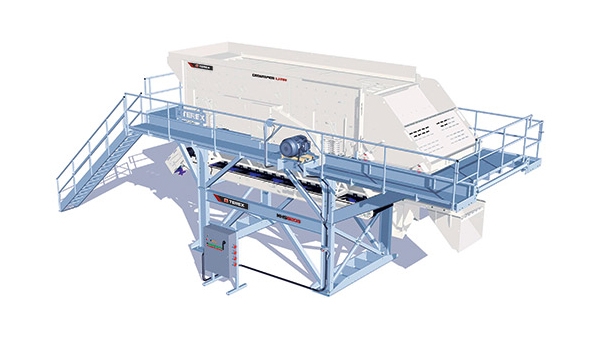

Module à crible horizontal MHS8203

The MHS8203 Modular Horizontal Screen features the large capacity 8' x 20' (2438mm x 6096mm) Terex® Cedarapids LJ-TSV screen with its legendary El-JayTM oval stroke action. Set-up time and ease of operation is aided by the simplicity of the modular product range. All of our modular crushers and modular screens bolt together on site and require minimal on-site wiring. Designed with logistics in mind, the MHS8203 Horizontal Screen Module, including all its components, is easily transported in shipping containers.

The modular product line consists of several pre-designed static and semi-static crushing and screening “plug and play” modules. This simple but effective product line gives flexibility to customers to choose “ready to work” modules to create the plant needed for a variety of applications. All modules are designed to fit and work together interchangeably.

Module Structure

- Bolts together on site, quick set-up time with basic tools ;

- Pre-wired “plug and play” design, minimal on-site wiring ;

- Robust weather-protected control panel with user-friendly controls ;

- Galvanized steel structure including walkways, stairs and guard rails ;

- Extra-heavy-duty I-beam frame ;

- Rigid diagonal truss construction ;

- Integrated rolling chute mechanism and integrated trouser leg chutes ;

- CE compliant module structure and components ;

- Systematically packed in shipping containers for quick site setup and easy transport.

Terex® Cedarapids LJ-TSV Horizontal Screen

- 8' x 20' (2438mm x 6096mm) 3-deck LJ-TSV8203-38 horizontal screen with El-JayTM oval stroke design ;

- Three-shaft vibrator mechanism with adjustable stroke angle, stroke length, and speed ;

- 25% thicker 5/16" (8 mm) grade 50 high strength steel side plates ;

- Heavy-duty fully braced single crown steel deck construction ;

- Exclusive patented and patent-pending features for durability and easy maintenance :

- Low maintenance vibration damper system ;

- “Flow-through” bearing lubrication ;

- Baffle splash lubrication system ;

- Double O-ring sealed for life vibrator construction.

- Spherical washer design eliminates sidewall welds ;

- Huck-bolted screen box construction (no welds) ;

- Extended life coil spring suspension ;

- Replaceable bolt-on spring guides ;

- Gland type non-wearing shaft seal ;

- Tool-less oil level sight glasses.

Underscreen Conveyor

- 60" (1524mm) fully skirted underscreen fines conveyor ;

- 20 hp (15kW) standard drive electric motor and gearbox ;

- 3-ply belt with vulcanized splice and easy access belt take-ups ;

- High performance belt wiper ;

- CEMA C 20° troughing rolls.

Blending Chutes

- 4-section (25%) blending gate system for all decks ;

- Product combinations: bottom deck & fines; center & bottom decks; top & center decks ;

- Heavy-duty AR 400 liners.

Power Panel

- Electric power panel for screen and on plant collection conveyor, 50 hz standard ;

- Additional motor starters for off-plant feed conveyor and four product conveyors.